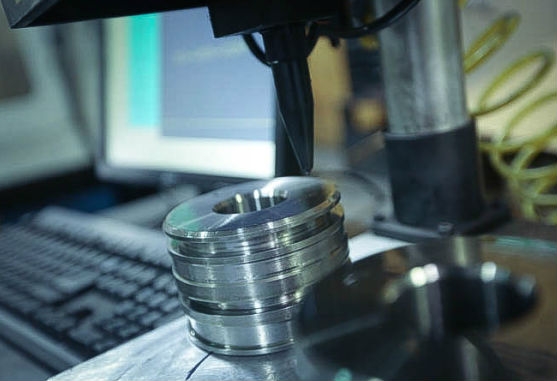

Quality CNC Machining Services in Los Angeles

Elevate your projects with Los Angeles CNC machining excellence

Lawton Standard brings quality CNC machining services to Los Angeles, focusing on better pricing and superior parts. Our state-of-the-art facilities and efficient processes allow us to offer cost-effective solutions without compromising precision or quality. Whether your project requires intricate components or large-scale production, our CNC machining services in Los Angeles ensure you get the best value for your investment.

Competitive pricing for superior machined parts

In Los Angeles, we understand the demand for efficiency and affordability. Our CNC machining services not only provide quality components but also guarantee cost-effectiveness. At Lawton Standard, we leverage our expertise and technology to streamline processes, offering competitive pricing while maintaining the high standards that define our Los Angeles CNC machining services.