V-3 65-45-12 ASTM A536 SG Ductile Iron Stock Supplier

V-3 65-45-12 ASTM a536 SG ductile iron features unmatched machinability

Continuous Cast Iron Suppliers >>>>> Ductile Iron >>>>> V-3 65-45-12 ASTM a536 SG

|

|||||||||||||||

|

Material Properties |

|

| Tensile strength | 65,000 psi |

| Yield strength | 45,000 psi |

| Elongation, % | 12% |

| Brinell hardness range | 131/220 |

| Microstructure, as cast | Ferritic |

| Machinability | Very good |

| Heat treatment | Full Anneal or Normalize |

| ASTM Specification | A-536 |

V-3 (65-45-12) ductile iron has a tensile strength of 65,000 psi, a yield strength of 45,000 psi, and 12% elongation. Its density of 0.256 pounds per cubic inch (lb/in³) or 7.1 grams per cubic centimeter (g/cm³) is significantly denser than aluminum but slightly less dense than steel. 65-45-12 ductile iron hardness ranges from 131 to 220 BHN. The microstructure as cast is ferritic.

The fine ferritic structure makes V-3 65-45-12 ductile iron the easiest to machine of the three grades of Versa-Bar. V-3 ductile iron offers high spindle speeds, less tool wear, and better finishes. It’s widely used for pistons in the hydraulics industry. 65-45-12 grade ductile iron provides excellent wear resistance and high strength in metal-to-metal applications.

V-3 continuous cast SG ductile iron as a steel replacement

When compared directly to 1144 steel (including material cost), our machining tests showed the V-3 ductile iron cost up to 20% less to produce the same part. All grades of continuous cast iron from Lawton Standard offer tremendous cost savings. Versa-Bar ductile iron is an excellent, more affordable alternative to steel and contains several benefits for production:

V-3 65-45-12 ductile iron machining services:

For many of the most common custom components in the automotive, fluid power, and transportation industries, 65-45-12 Versa-Bar ductile iron offers you a lower price and higher quality than any steel. Lawton Standard offers custom CNC Machining Services and in-house casting to support lean manufacturing.

V-3 65-45-12 ductile iron stock material

Iron bar, rounds, and rods

Our custom-cut ductile iron products include rods, bars, and rounds. Looking for more information about our stock? Call us today!

Iron tubes

Condensing your saturated range of options for ordering 65-45-12 ductile iron tubing is as easy as heading straight to Lawton Standard. Ask us about our custom cast tubing today.

| Custom I.D.s & O.D.s | Up to 20" |

|---|---|

| Material | Raw Iron |

Cast iron cut pieces

We proudly offer custom-made V-3 65-45-12 ductile iron cut pieces as part of our large inventory of raw iron products. Contact us today about your project.

Cast iron plates

Our custom V-3 65-45-12 ductile iron plates are perfect for machining and fabricating bearings and rotors. Contact us about our cast iron plates for your project.

Cast iron rectangular bar

Lawton Standard's rectangular bar stock is a high-quality material for machining and heavy equipment applications. Contact us for information on ordering and pricing rectangular stock today.

Versa-Bar V-3 65-45-12 ductile iron for greater durability and longer life

V-3 65-45-12 ductile iron features unparalleled machinability.

Versa-Bar ductile iron offers you unprecedented machinability and performance. Versa-Bar’s continuous casting process provides uniformity and consistent soundness you’ll never achieve by sand casting. Turning speeds of 30% or more result in increased tool life and decreased labor costs.

The high graphite flake content in ASTM A536 SG Versa-Bar means that every bar contains tiny recesses, which retain oil, ensuring that oil-lubricated parts stay lubricated for longer. A well-dispersed and retained lubricant means that a part made of Versa-Bar has a significantly better chance of survival should oil be lost.

Versa-Bar is the true hydraulic metal. Its natural, non-abrasive quality gives it extremely high wearability, making it an opportunity you can’t afford to pass up.

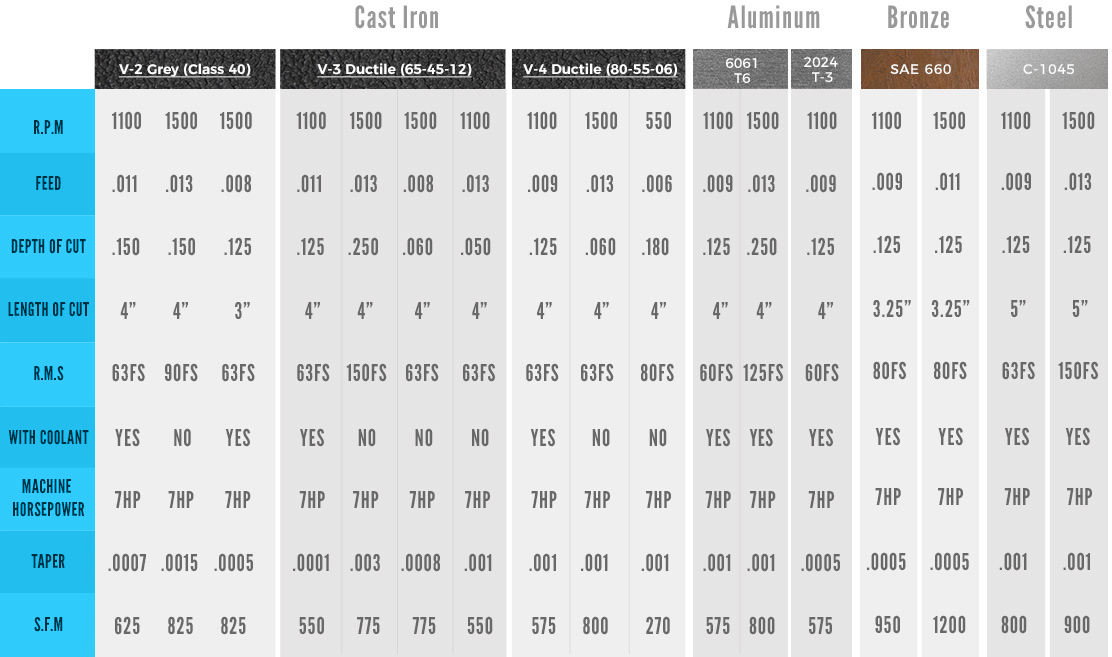

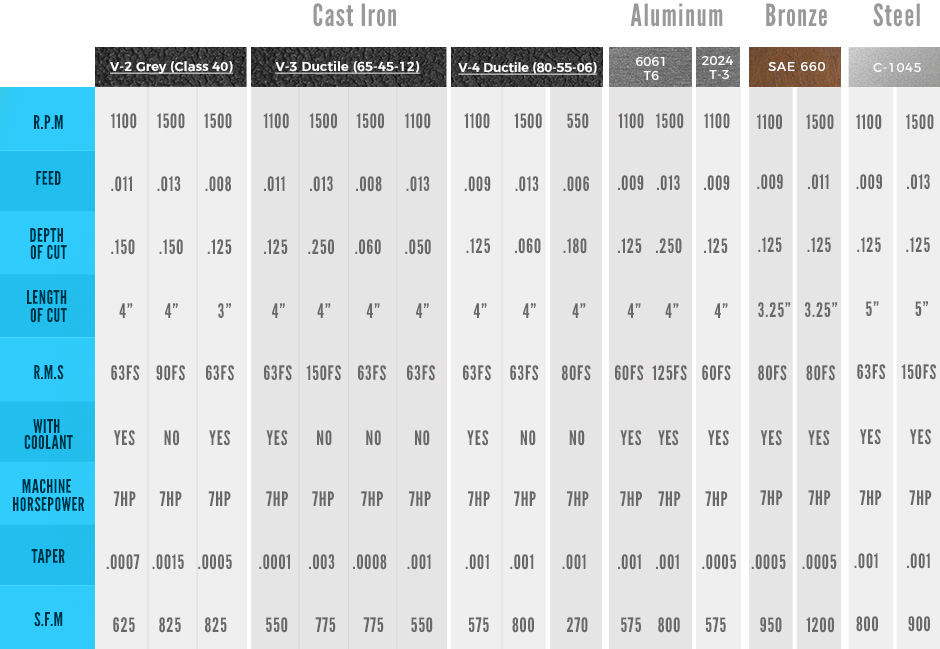

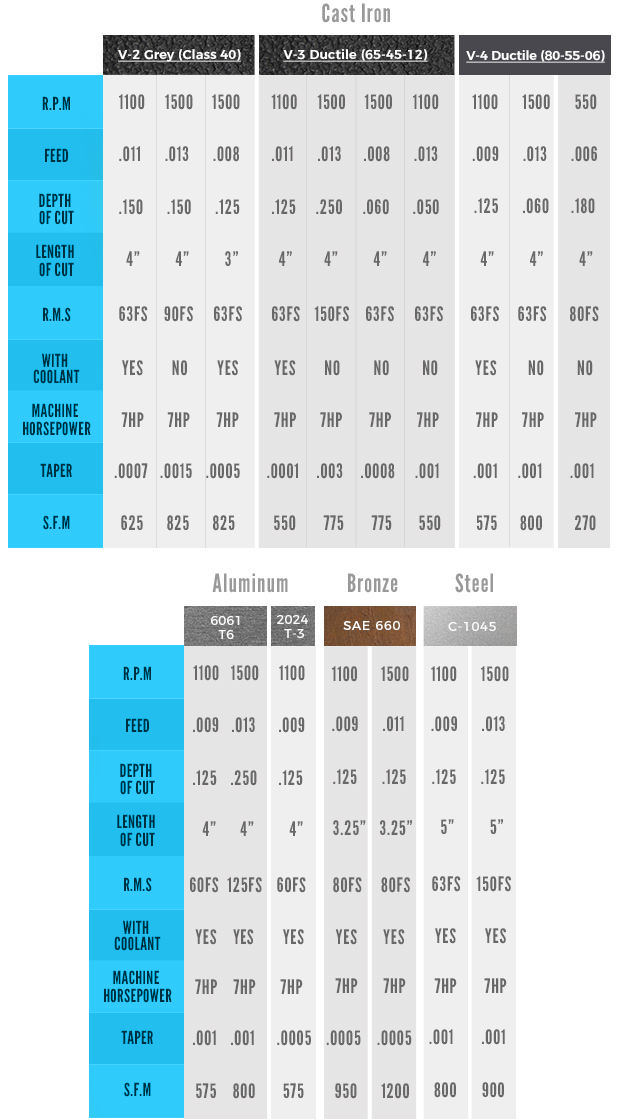

V-3 65-45-12 ductile cast iron beats aluminum, bronze, and steel in basic field comparison testing

Operators were asked to achieve the best surface finish per minute (SFM) on 65-45-12 Versa-Bar ductile cast iron and maintain comparable cut and surface roughness depths to those of aluminum, bronze, and steel grades.

The machine used was a 7 hp lathe set up to produce hydraulic cylinder pistons. The cutting tools used in the analysis were a Valenite VC 67 Carbide Insert.

Here are the results:

The results, reached through conventional tooling and equipment, demonstrate Versa-Bar's competitive superiority.

Contact V-3 65-45-12 ductile iron suppliers for more information regarding gray and ductile iron for the following areas beyond Milwaukee, New York, North Carolina, California, Texas, Maryland, and Illinois.